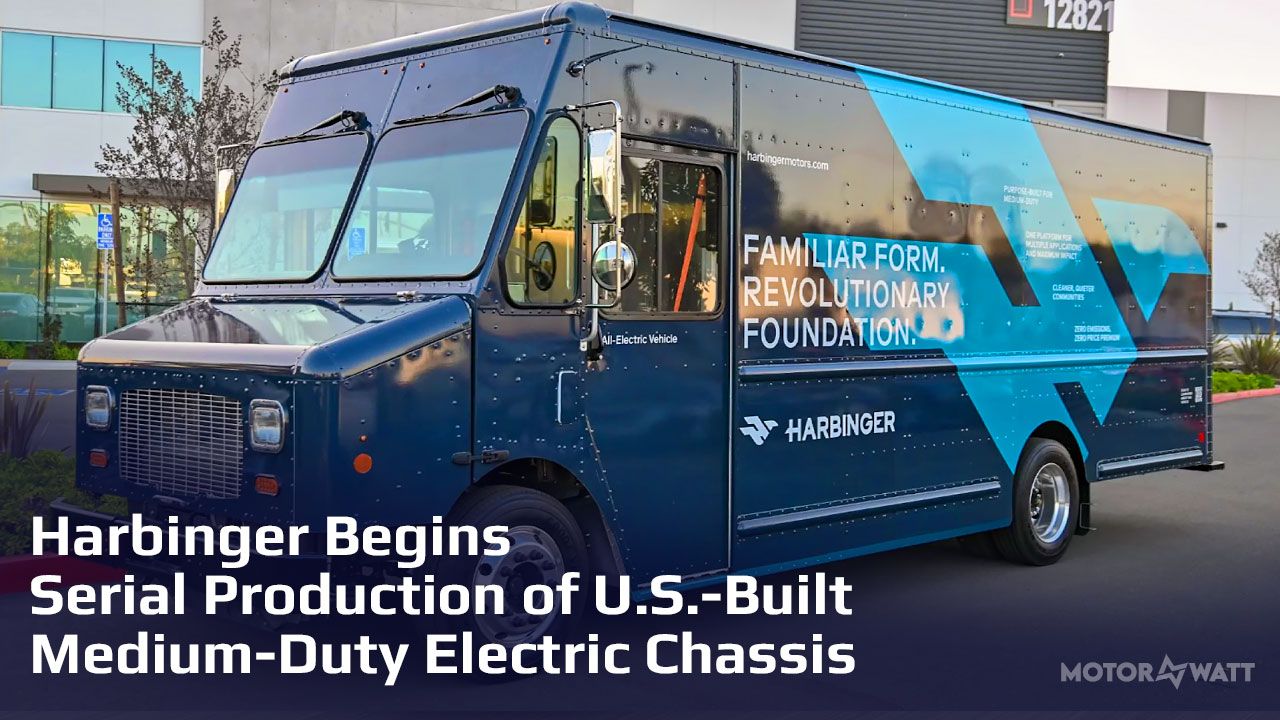

Harbinger Begins Serial Production of U.S.-Built Medium-Duty Electric Chassis

Share this article in Social Media:

Harbinger, a U.S. electric truck maker, has started serial production of its medium-duty EV chassis in California. With 4,690 orders valued at $500M and $100M in Series B funding, the vertically integrated company is reshaping American commercial EV manufacturing.

American EV startup Harbinger just hit a major milestone—officially launching serial production of its medium-duty electric chassis in Garden Grove, California. With over 100 units built to date, the company is making serious strides in a segment dominated by legacy diesel and gas platforms. But this isn’t your average EV story. Harbinger’s doing things differently—and it might be exactly what the U.S. electric truck market needs right now.

While big names chase passenger EV headlines, Harbinger is focused on the unsung heroes of logistics: walk-in vans, box trucks, RVs, delivery vans, and emergency vehicles. And they’re not just assembling—they’re building the drivetrain and battery packs in-house. In an industry filled with third-party suppliers, this level of vertical integration sets Harbinger apart.

Made in California: Harbinger’s Medium-Duty Electric Chassis Platform

Operating out of its Garden Grove facility, Harbinger manufactures stripped electric chassis tailored specifically for medium-duty vehicle applications. These chassis form the base for a wide variety of upfits, from FedEx-style vans to Class A RVs. This modularity means fleet operators don’t have to compromise—they can electrify without changing how they operate.

By building the electric drivetrain and battery systems in-house, Harbinger improves quality control and reduces costs. And it’s the only truck manufacturer in the country doing this at scale, reinforcing its position as a vertically integrated EV leader. That’s a big deal when you’re competing against traditional OEMs who often outsource major vehicle components.

Key Partnerships with THOR Industries, ETHERO, and Bruckner’s Truck

Harbinger isn’t just spinning its wheels—it’s building real-world relationships. The company has landed strategic partnerships with big players, including THOR Industries (the world’s largest RV maker), ETHERO Truck + Energy, and Bruckner’s Truck. These deals give Harbinger access to multiple market verticals and fast-track its chassis into fleet hands nationwide.

From luxury RVs to last-mile delivery, the applications are broad—and the demand is real. These partnerships validate Harbinger’s flexible platform design and its promise of U.S.-built EV chassis that meet both performance and price needs.

$100M Series B Funding Fuels Nationwide Expansion

In January 2025, Harbinger secured $100 million in Series B funding. The round was co-led by Capricorn’s Technology Impact Fund and Leitmotif, and it’s set to accelerate everything from production ramp-ups to service infrastructure. If you’re wondering whether investors believe in the company—this round answers that loud and clear.

The cash injection supports more than just manufacturing. Harbinger is also building out its sales, parts, and service operations across the U.S.—a smart move in a market that often overlooks the logistics of fleet support. They’re not just selling chassis—they’re building a national EV ecosystem.

Price Parity with Diesel—Thanks to Vertical Integration and Incentives

One of Harbinger’s biggest selling points is affordability. Thanks to its vertically integrated manufacturing and control over its supply chain, Harbinger can offer its chassis at price parity with gasoline and diesel platforms—especially after applying federal EV tax credits and clean commercial vehicle incentives.

This means fleets can go electric without paying a premium, removing one of the biggest adoption barriers. For many commercial buyers, it’s not about luxury or speed—it’s about total cost of ownership. Harbinger’s got that formula figured out.

4,690 Orders and $500 Million Pipeline: Harbinger’s Market Impact

As of Q1 2025, Harbinger has logged 4,690 vehicle orders worth approximately $500 million. That’s not vaporware—that’s real demand from real customers. And it’s not all future-tense; more than 100 chassis have already rolled off the production line.

This early traction suggests that Harbinger’s timing couldn’t be better. With federal policies pushing for domestic EV production and major fleets seeking to cut emissions, the company is sitting at the intersection of market readiness and manufacturing capability.

Looking Ahead: Harbinger’s Role in American EV Manufacturing

As legacy automakers struggle to electrify their medium-duty lines, Harbinger is proving that focused innovation and vertical control can move the needle faster. Its American-made electric chassis aren’t just about sustainability—they’re about independence from global supply chain snags and unpredictable sourcing costs.

With more orders on the way, financial backing in the bank, and production humming in California, Harbinger is positioning itself as the go-to electric chassis provider for America’s commercial and specialty vehicles. If you haven’t heard of them yet, now’s the time to pay attention.